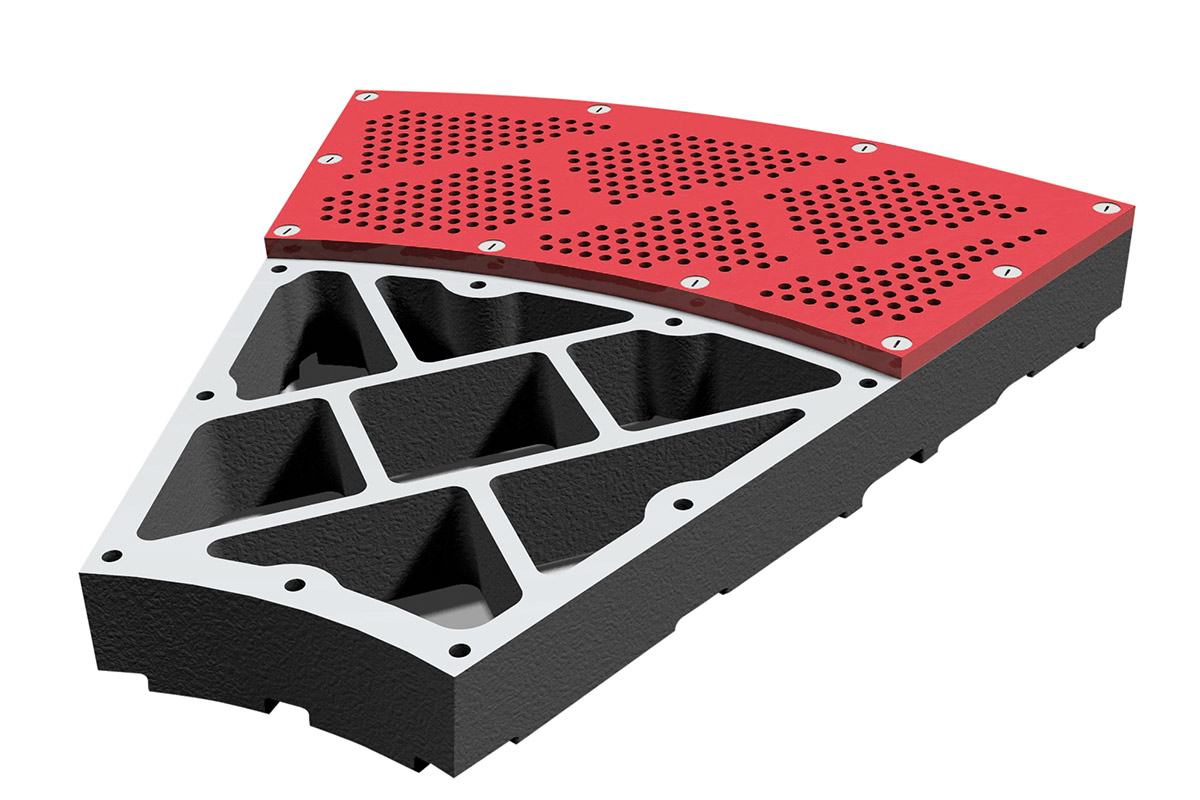

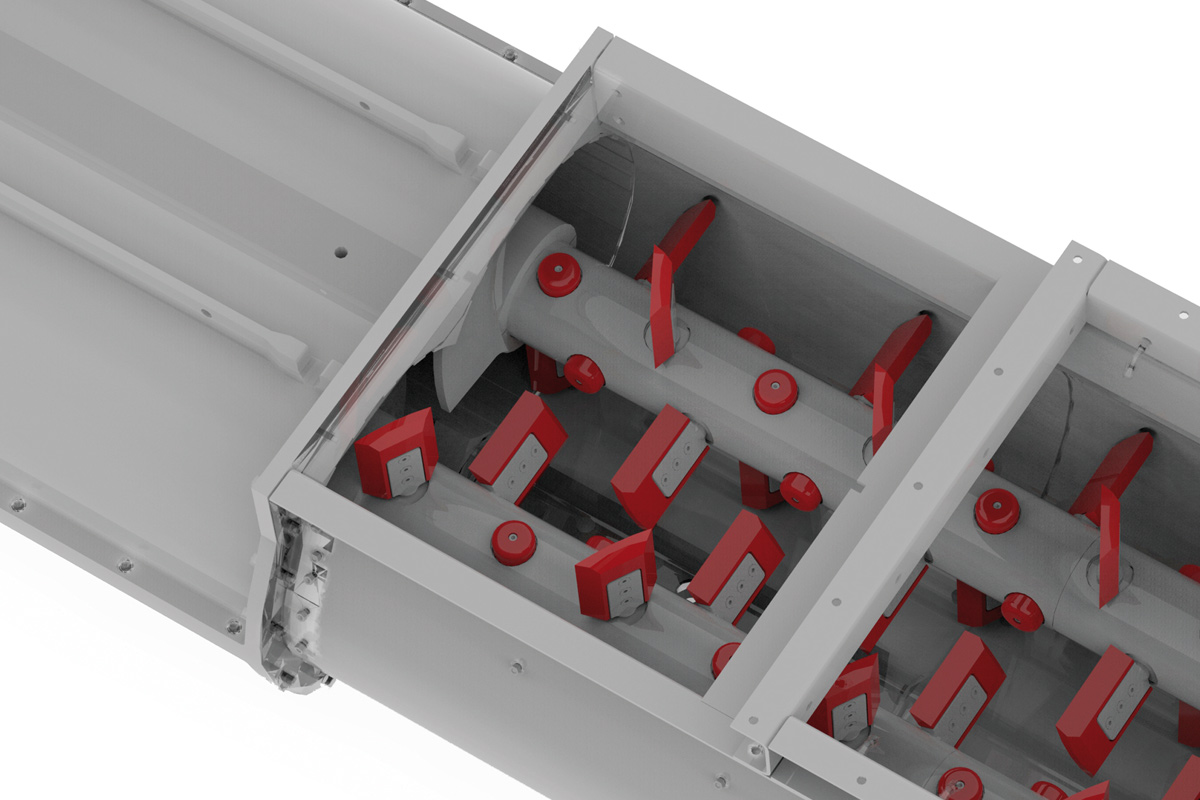

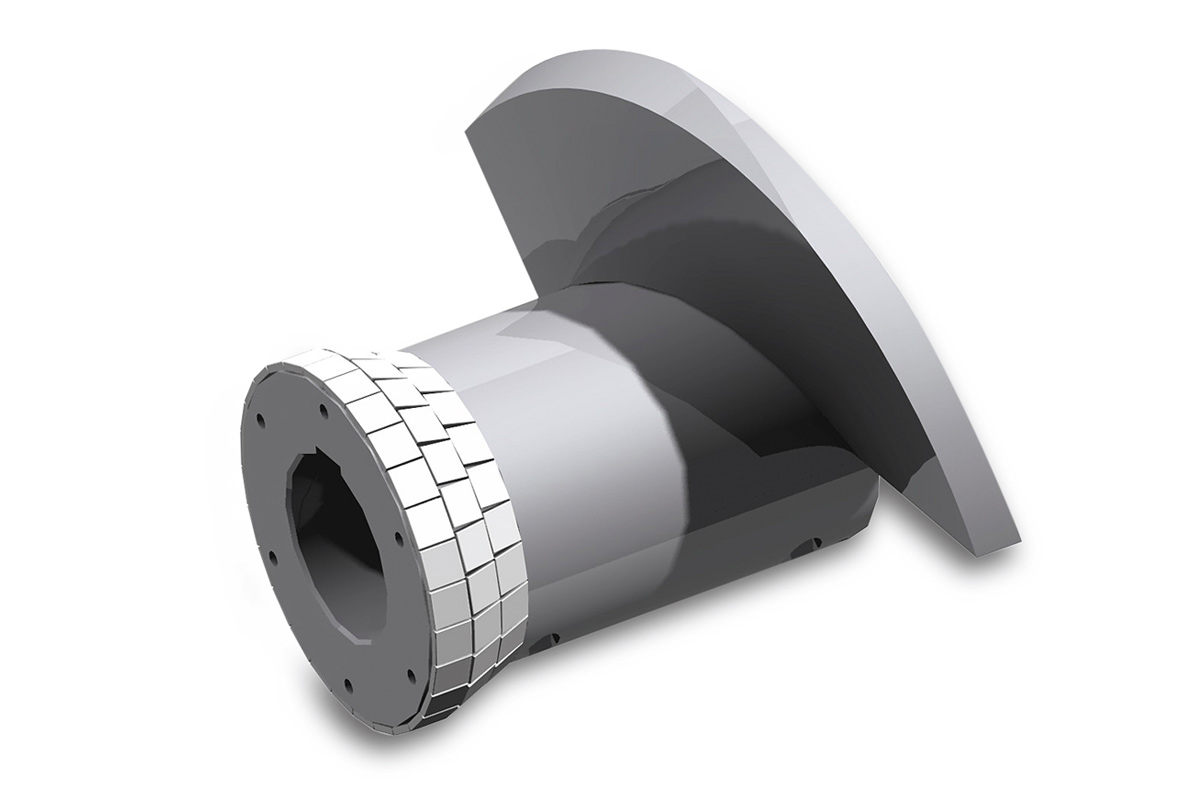

At HÄNDLE’s, research & development is not confined to new machines and processes. Our spare and wear parts are continually improved and accommodated to the latest technical insights. Original HÄNDLE parts are therefore known for their optimized wear behavior, long service lives and ease of handling for replacement. As such, they help maximize the availability of your machines (including those of other makes) while minimizing unscheduled outages.

- Continually improved and accommodated to the latest technical insights

- Flexible and fast single-item production

- More than 6.500 different spare- and wear parts in stock

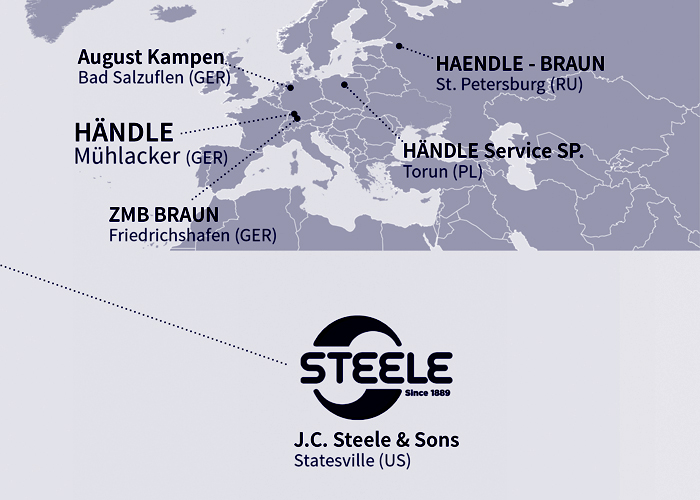

Your contacts:

- Martin Metzger, Phone +49(0)7041 891-386, M.Metzger@haendle.com

- Jürgen Mahler, Phone +49(0)7041 891-217, J.Mahler@haendle.com

- Christoph Treut, Phone +49(0)7041 891-207, C.Treut@haendle.com

- Andreas Jung, Phone +49(0)7041 891-214, A.Jung@haendle.com