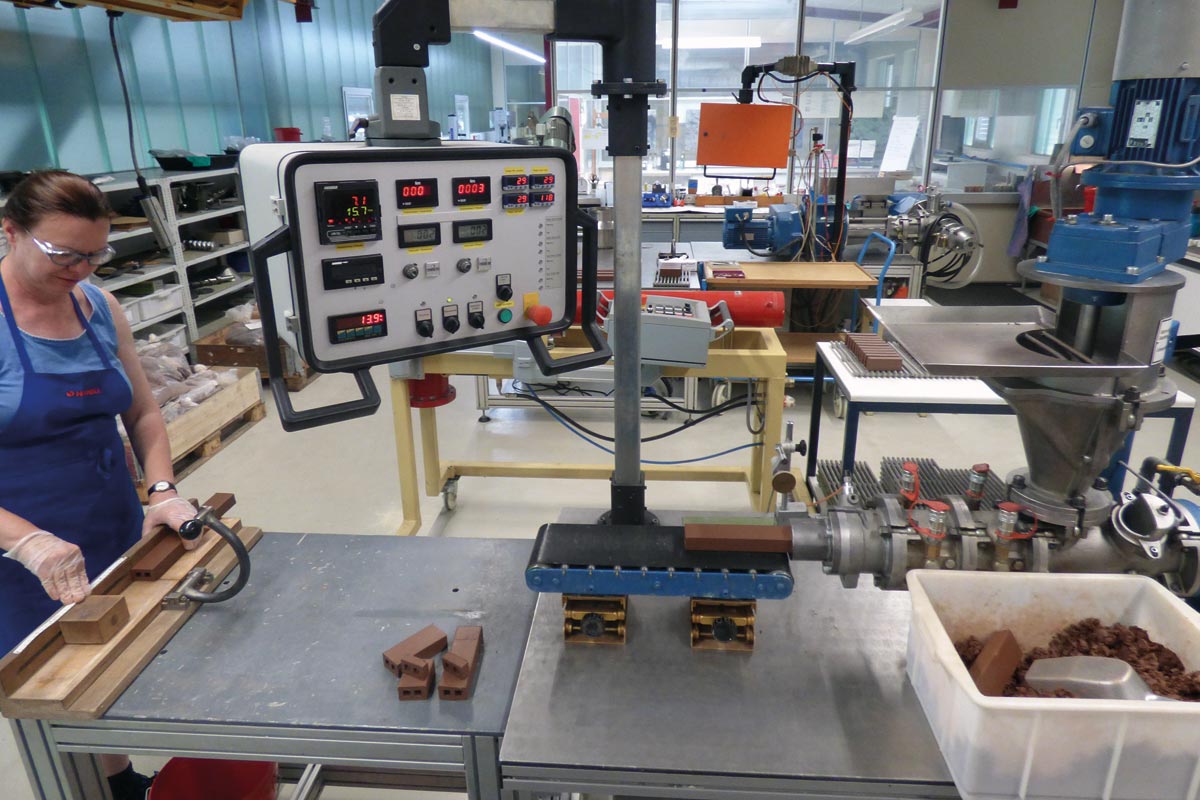

We work out body- and process-specific solutions for our customers in our own laboratory. For more than 70 years now, the HÄNDLE laboratory has enjoyed an especially good reputation for near-practice research.

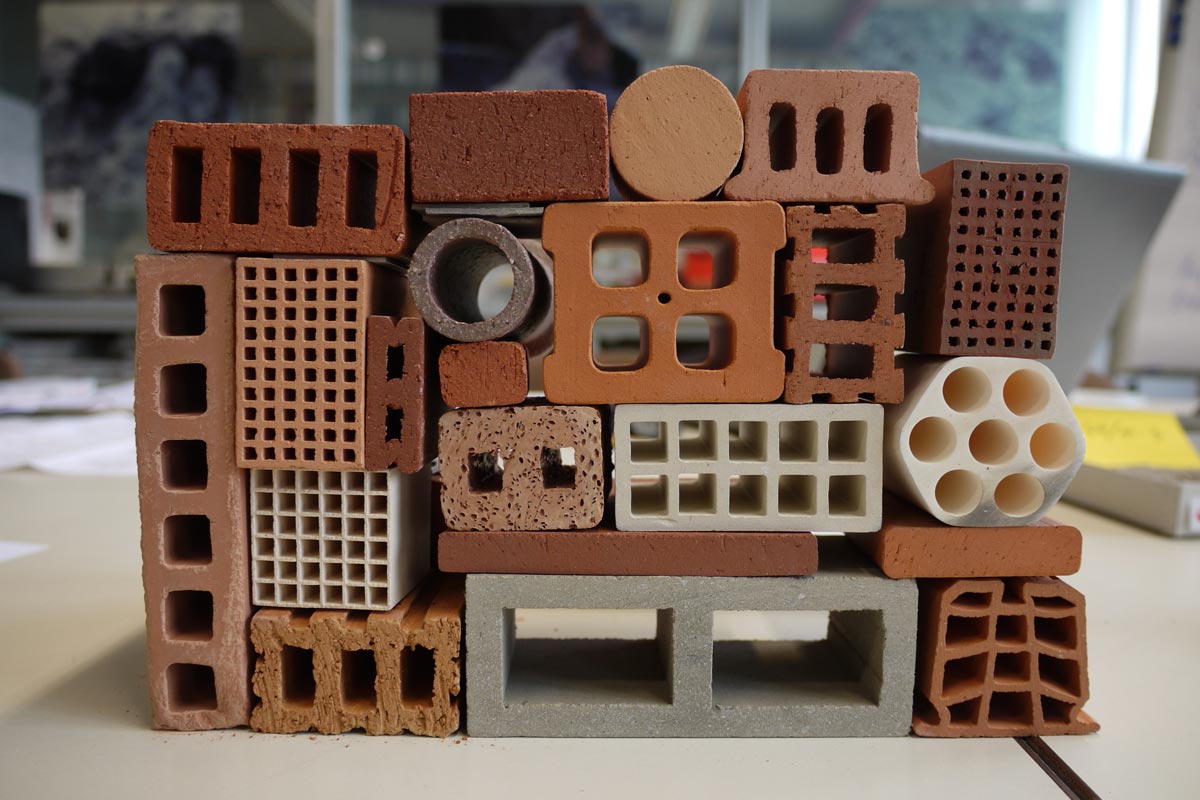

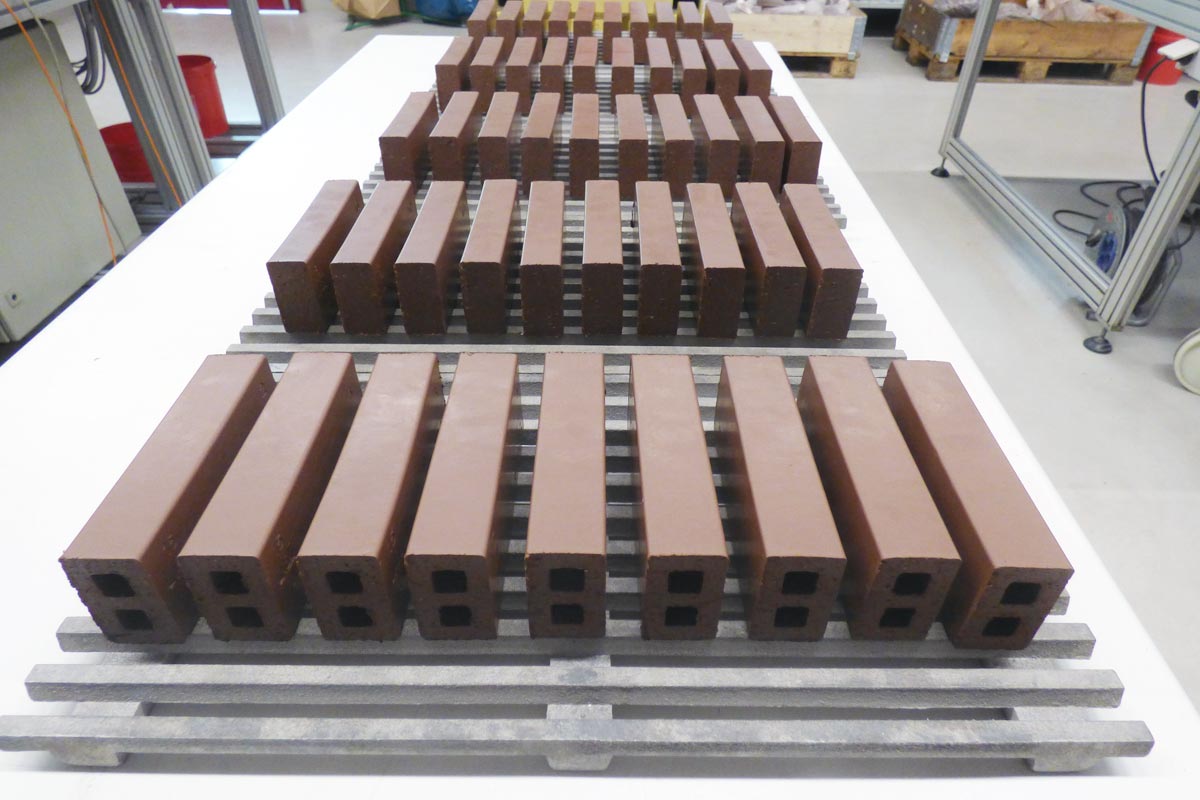

The experience drawn from that work provides the know-how we need for on-target planning and implementation of new production facilities and for ensuring the optimal operation of existing plant and equipment. Our test spectrum covers a wide range of ceramic products and special products. Over the past few years, we have developed special tests for simulating the work of preparation and extrusion machines on a laboratory scale. These tests enable reliable implementation of the laboratory results into practice and thus process-optimized and energy-efficient manufacturing processes for our customers.

Together with ZMB BRAUN, we develop optimized laboratory dies for our extrusion tests. The resultant knowledge is incorporated into the individual configuration of the production machines.

This may also interest you: HÄNDLE Laboratory fine roller mill and HÄNDLE laboratory de-airing extrusion unit